Basic Info.

Model NO.

RAY-LH291#

Material

Optical Glass/Fused Silica/Borosillice Glass/CaF2

Lenses Color

Clear

Certification

RoHS, ISO9001, CE, ISO14000 & BV

Customized

Customized

Coating

Polishing/Coating/Uncoating, etc

Polishing Materials Type I

Quartz/Silicon/Sapphire Ingot/Graphite

Polishing Materials Type II

Fused Slica/Sic/CaF2/Baf2/Zns/Znse

Max.Iob Polishing Size

D1300mm

Max. Iob Polishing Thickness

300mm

Iob Polishing Accuracy

RMS Less Than 5nm

Ion Source

German RF Ion Source

Movement Controlling Method

3-Axis Linkage

Processing Shapes

Planar, Spherical, Aspheric, Ultrathin, Cylindrica

Transport Package

Carton & Wood Case

Specification

Custom as per demand

Trademark

Raytek

Origin

China

HS Code

281122900

Production Capacity

1000000PCS Per Year

Product Description

General Introduction:

From prototype to high-volume production Raytek Optics is dedicated to manufacturing custom plano optics to meet your precise specifications. Since 2017, Raytek Optics has built a worldwide reputation in custom optics manufacturing pairing traditional craftsmanship with leading-edge technology. Our 50,000 sq. ft. facility houses the larger collection of cnc cutting machines,cnc milling machine centers, double-sided polishing machines,PIB polishing machine, MRF polishing machines, etc in Shanghai,China.

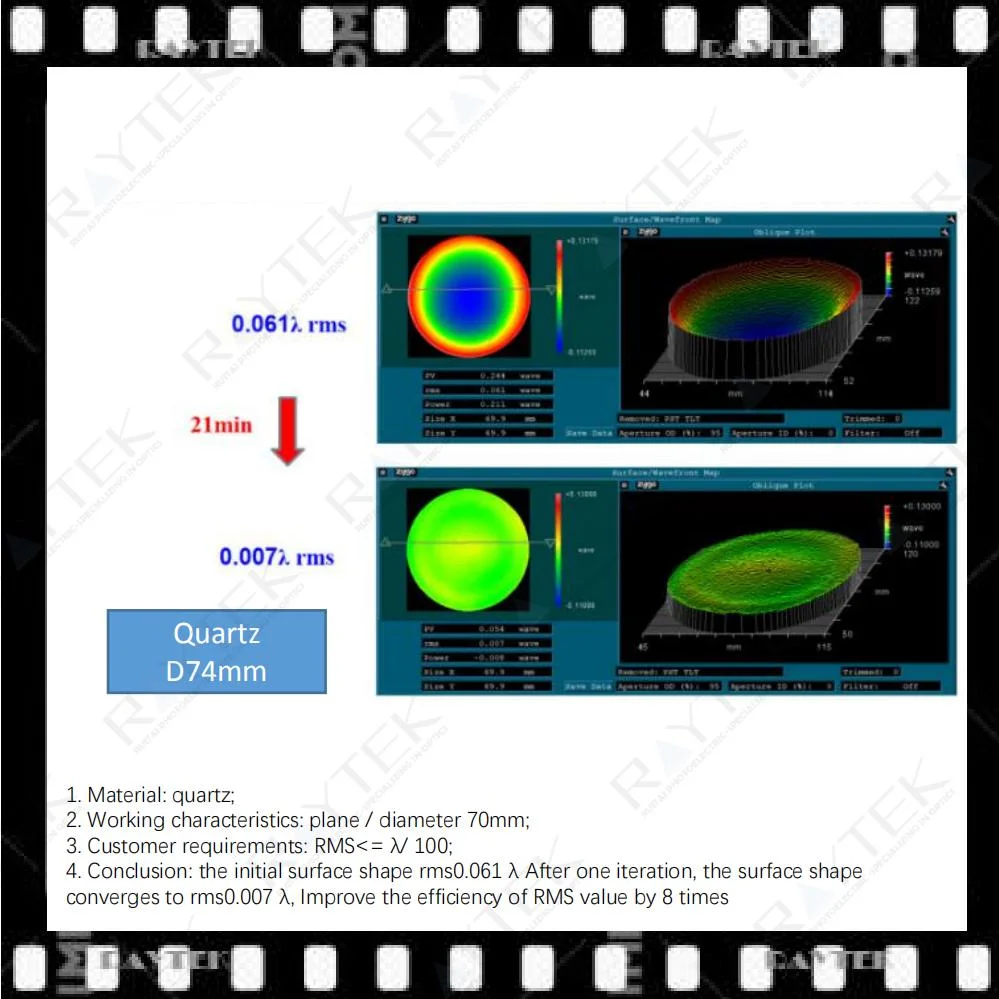

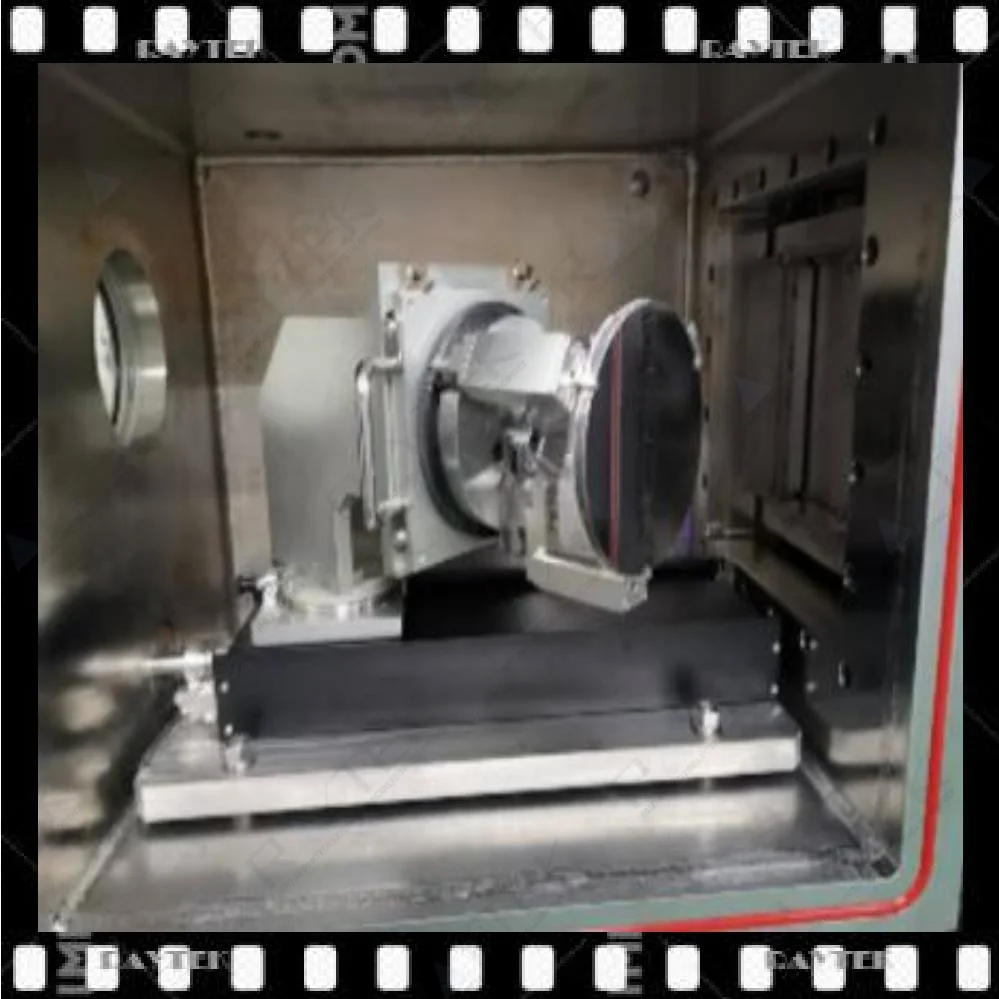

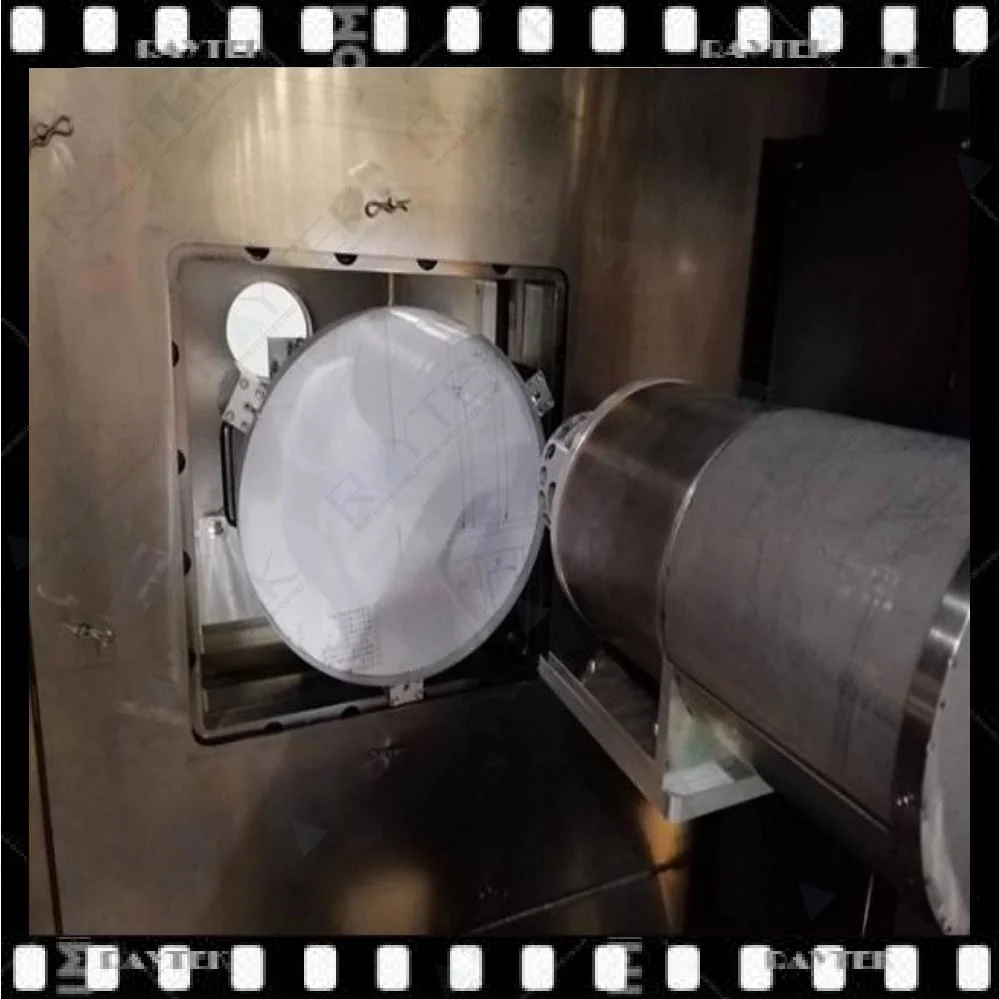

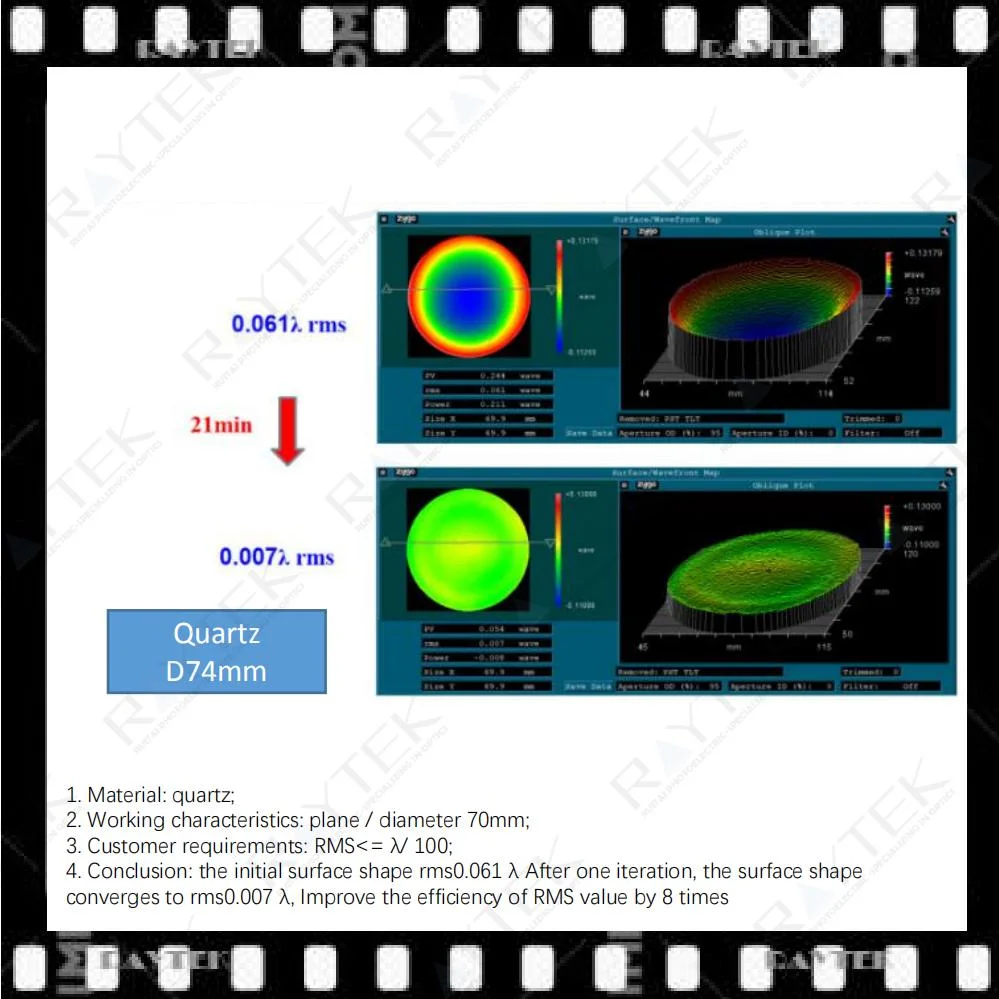

Custom Manufacturing Capacity 6: Ion Beam Polishing(IOB)

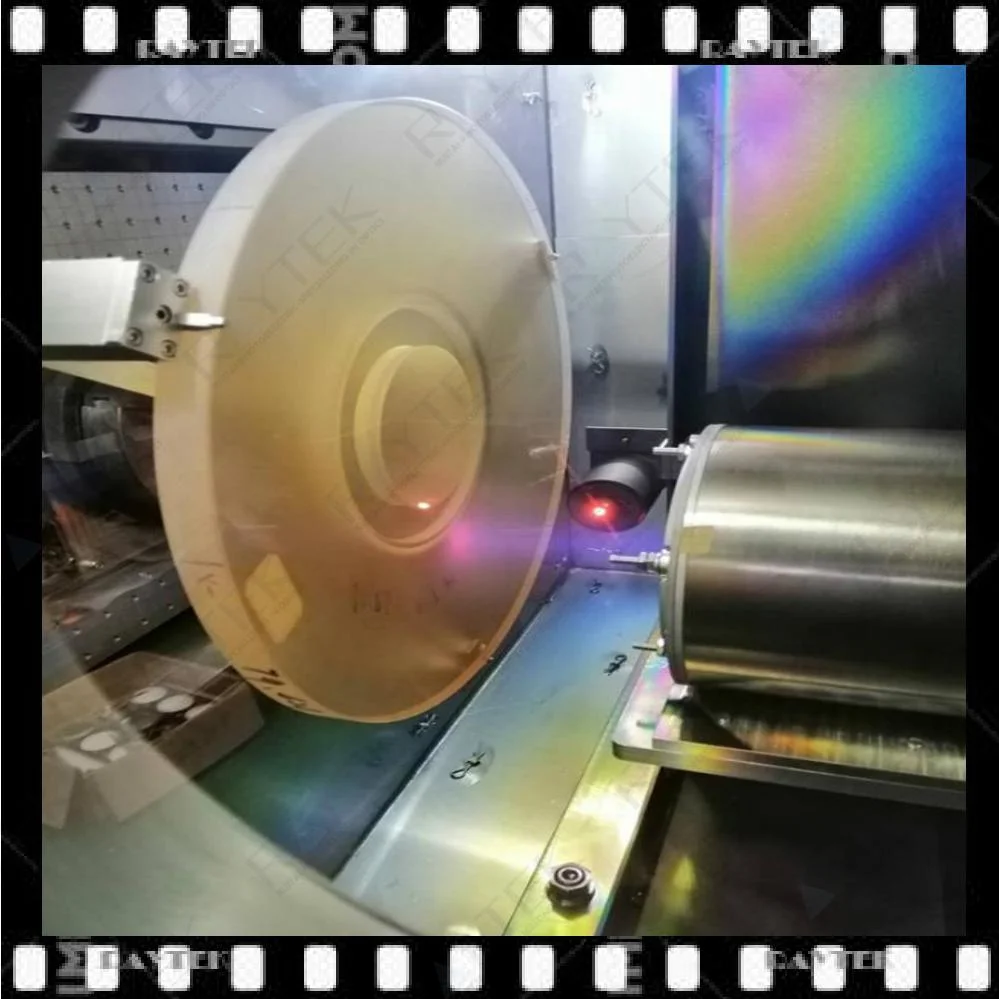

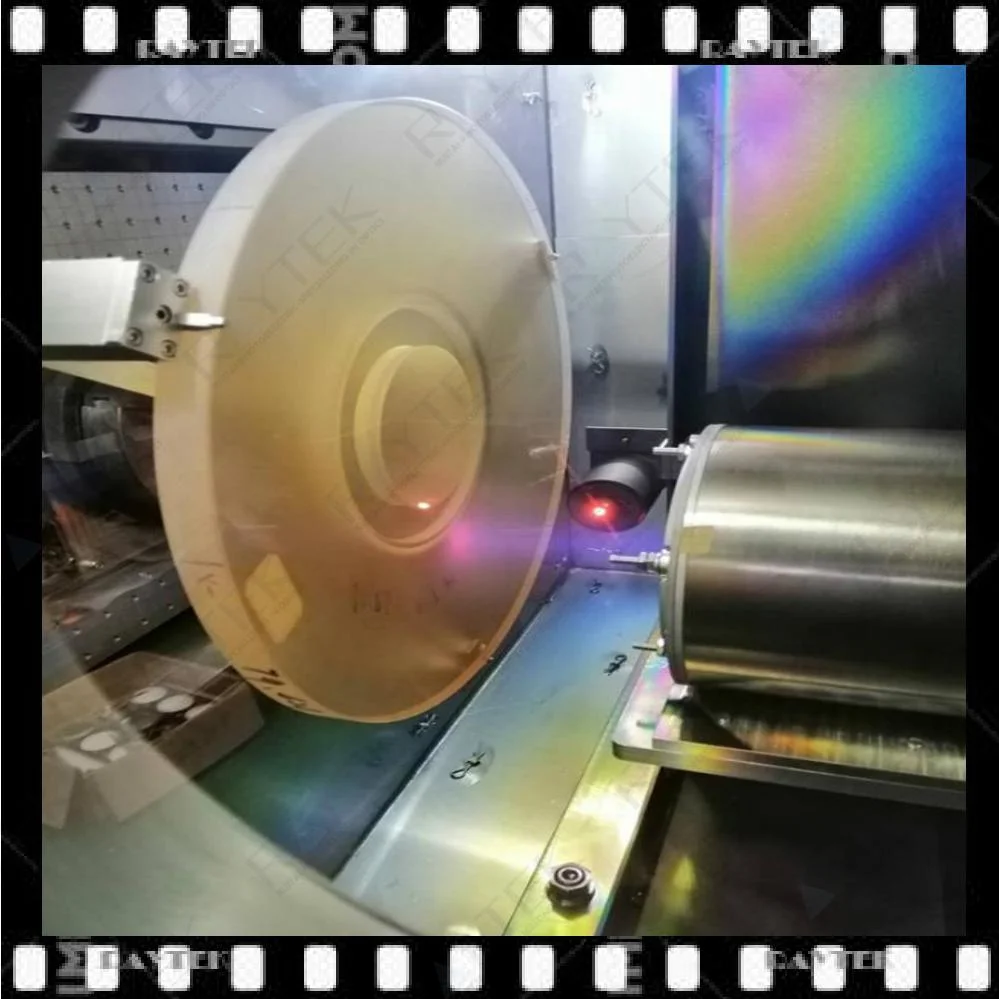

Raytek ion beam polishing(IBP) technology is based on the principle of ion sputtering. In the vacuum state, the plasma energy beam is generated by the ion source. The beam bombards the surface of the workpiece to produce atomic level material removal, so as to realize the high-precision machining of optical elements.

Ion beam polishing can precisely polish the surface of workpiece. And the prepared cross section can be used to observe the microstructure by light microscope, SEM, EBSD and AFM; The energy of ion beam gun is about 0 keV - 8 keV, which can cover high and low energy at the same time without changing the gun; The angle between the ion beam gun and the workpiece: - 100~ + 100, By changing the angle between the ion gun and the sample, the 3D information of the sample can be obtained, and the high depth resolution can be obtained;

Main Processing Technical Capacity Data:

Main Cutting Technologies Advantages:

1).Using 40mm RF ion source, the removal stability is better than 5%, which ensures the stability of polishing quality;

2).With high machining accuracy, sub nanometer precision machining can be realized;

3).It can be equipped with different apertures and grids, and the processing beam spot can be adjusted from 1 mm to 40 mm;

4).High removal efficiency, volume removal rate 0.0001-0.12mm ^ 3 / min; The removal efficiency can be adjusted, and different removal efficiencies can be set according to different precision. The highest removal efficiency is not lower than MRF and CCOS;

5).It can process most optical materials, including optical white glass (SiO2, K9, ubk7, etc.), infrared materials (Si, Ge, CaF2, ZnSe, ZnS, etc.), crystal materials (KDP, YAG, etc.) and metal materials;

6).Super high efficiency polishing process, the auxiliary cavity adopts three position structure, through the shift of position to achieve refueling, to achieve 24-hour uninterrupted processing;

7).Intelligent Faraday cup scanning, real-time monitoring of ion beam parameters and compensation of beam spot center position deviation, to ensure the precision and quality of polished surface;

8).The process software with angle error and machining error compensation can realize full digital control and ensure the machining accuracy at nanometer level;

9).The non-contact machining method can process arbitrary shape surface;

10).There is no subsurface damage;

11).For example, for YAG or single crystal SiC, the removal efficiency of ion beam is only one third of that of quartz, while for MRF and CCOS, the removal efficiency is one thirtieth to one tenth of that of quartz

12).The medium and low frequency errors can be repaired, and the medium and high frequency errors are not produced in the machining process;

Main Cooperation Materials Manufacturers:

CORNING, OHARA, SCHOTT, LEONI, AGC,HELLMA, NIKON,VITRON,C-LASER,ETC

Main Export Countries & Areas:

Usa, Uk, Japan, Germany, Spain, France, Swiss, Korea, Russia, Pakistan, India, Portugal, Canada, New Zealand, Australia, Saudi Arab, Turkey, Finland, Poland ,etc.

Raytekoptics Extra value added services offered:

1). Optical workcraft & process solution design;

2). Rough processing raw materials;

3). Semi finishing raw materials;

4). Fabricate custom sizes and shapes;

5). Design and supply custom coatings;

6). Modify and resurface customer supplied materials;

7). Drill holes, notch glass and provide beveled substrates;

8). Precision polish optics with non-standard aspect ratios;

Payment Method: by T/T or Western Union.

Delivery time: 7-10 days.

Quality Warranty: Ruitaiphotoelectric(Raytekoptics) offers quality warranty for our optics products & OEM & ODM service with "3R" policy--return, replace & refund policy.

For any inferior-quality products, Ruitaiphotoelectric(Raytekoptics) is responsible for return, replacement and refund.

From prototype to high-volume production Raytek Optics is dedicated to manufacturing custom plano optics to meet your precise specifications. Since 2017, Raytek Optics has built a worldwide reputation in custom optics manufacturing pairing traditional craftsmanship with leading-edge technology. Our 50,000 sq. ft. facility houses the larger collection of cnc cutting machines,cnc milling machine centers, double-sided polishing machines,PIB polishing machine, MRF polishing machines, etc in Shanghai,China.

Custom Manufacturing Capacity 6: Ion Beam Polishing(IOB)

Raytek ion beam polishing(IBP) technology is based on the principle of ion sputtering. In the vacuum state, the plasma energy beam is generated by the ion source. The beam bombards the surface of the workpiece to produce atomic level material removal, so as to realize the high-precision machining of optical elements.

Ion beam polishing can precisely polish the surface of workpiece. And the prepared cross section can be used to observe the microstructure by light microscope, SEM, EBSD and AFM; The energy of ion beam gun is about 0 keV - 8 keV, which can cover high and low energy at the same time without changing the gun; The angle between the ion beam gun and the workpiece: - 100~ + 100, By changing the angle between the ion gun and the sample, the 3D information of the sample can be obtained, and the high depth resolution can be obtained;

Main Processing Technical Capacity Data:

| Specifications | Manufacturing Limits |

| Processing Workcrafts | Ion Beam Polishing(IBF) |

| Diameter | ≤1300mm (± 0.010mm) |

| Length | ≤1300mm (± 0.010mm) |

| Width | ≤1300mm (± 0.010mm) |

| Thickness | ≤300mm (± 0.01mm) |

| IBF Accuracy | RMS≤5nm |

| Positioning Accuracy | ± 0.02mm |

| Repositioning Accuracy | ± 0.01mm |

| Movement Controlling Method | 3-axis linkage |

| XY Stroke Size | 0-1300mm |

| Z-axis Stroke Size | 0-300mm |

| A-axis Rotary Angle | A≥60° |

| Ion Source | German RF ion source |

| Maximum Beam Voltage | 2000V |

| Maximum Beam Currency | 1000mA |

| Elimination Function | Gaussian type, stability ≥ 95% |

| Working Vacuum | 5 × 10-3pa |

| Working Vacuum Establishment Time | ≤1.5 hours |

| Secondary Chamber Vacuum Build-up Time | ≤30 min |

| Materials For Processing | Fused silica / fused quartz/Silicon/CaF2/BaF2/ZnS/ZnSe Optical glass, silicon, infrared materials, YAG, sapphire |

| Processing Shapes | Planar, spherical, aspheric, ultrathin, cylindrical, off-axis, free-form surface |

Main Cutting Technologies Advantages:

1).Using 40mm RF ion source, the removal stability is better than 5%, which ensures the stability of polishing quality;

2).With high machining accuracy, sub nanometer precision machining can be realized;

3).It can be equipped with different apertures and grids, and the processing beam spot can be adjusted from 1 mm to 40 mm;

4).High removal efficiency, volume removal rate 0.0001-0.12mm ^ 3 / min; The removal efficiency can be adjusted, and different removal efficiencies can be set according to different precision. The highest removal efficiency is not lower than MRF and CCOS;

5).It can process most optical materials, including optical white glass (SiO2, K9, ubk7, etc.), infrared materials (Si, Ge, CaF2, ZnSe, ZnS, etc.), crystal materials (KDP, YAG, etc.) and metal materials;

6).Super high efficiency polishing process, the auxiliary cavity adopts three position structure, through the shift of position to achieve refueling, to achieve 24-hour uninterrupted processing;

7).Intelligent Faraday cup scanning, real-time monitoring of ion beam parameters and compensation of beam spot center position deviation, to ensure the precision and quality of polished surface;

8).The process software with angle error and machining error compensation can realize full digital control and ensure the machining accuracy at nanometer level;

9).The non-contact machining method can process arbitrary shape surface;

10).There is no subsurface damage;

11).For example, for YAG or single crystal SiC, the removal efficiency of ion beam is only one third of that of quartz, while for MRF and CCOS, the removal efficiency is one thirtieth to one tenth of that of quartz

12).The medium and low frequency errors can be repaired, and the medium and high frequency errors are not produced in the machining process;

Main Cooperation Materials Manufacturers:

CORNING, OHARA, SCHOTT, LEONI, AGC,HELLMA, NIKON,VITRON,C-LASER,ETC

Main Export Countries & Areas:

Usa, Uk, Japan, Germany, Spain, France, Swiss, Korea, Russia, Pakistan, India, Portugal, Canada, New Zealand, Australia, Saudi Arab, Turkey, Finland, Poland ,etc.

Raytekoptics Extra value added services offered:

1). Optical workcraft & process solution design;

2). Rough processing raw materials;

3). Semi finishing raw materials;

4). Fabricate custom sizes and shapes;

5). Design and supply custom coatings;

6). Modify and resurface customer supplied materials;

7). Drill holes, notch glass and provide beveled substrates;

8). Precision polish optics with non-standard aspect ratios;

Payment Method: by T/T or Western Union.

Delivery time: 7-10 days.

Quality Warranty: Ruitaiphotoelectric(Raytekoptics) offers quality warranty for our optics products & OEM & ODM service with "3R" policy--return, replace & refund policy.

For any inferior-quality products, Ruitaiphotoelectric(Raytekoptics) is responsible for return, replacement and refund.